With a grant from the farmer-driven Northern New York Agricultural Development Program, veterinarians Paul D. Virkler and Paula Ospina have begun developing e-learning modules to meet a need for dairy employee training. A report on phase one results is posted at nnyagdev.org.

“Initial hire and ongoing employee training is essential for dairy farm businesses. This project is developing a cloud-based way to improve dairy employee knowledge, skill-building, and consistency of performance, which, in turn, benefit cow health, productivity, and farm sustainability,” said Virkler, DVM, a veterinarian with Quality Milk Production Services in Canton.

“This initial project with on-farm participants provided excellent input for building employee-friendly e-learning modules that will engage dairy employees and enhance their knowledge, skills, and competency,” said Ospina, DVM, PhD, and dairy consultant.

Virkler and Ospina worked with 10 cooperating dairy farms throughout northern New York to pilot test module development with a focus on milker knowledge and skill, the efficient functioning of milking equipment, and cow health in terms of teat and udder hygiene.

A baseline survey identified areas of dairy parlor performance that could be enhanced to improve milk quality and reduce the risk of mastitis. Based on that survey, 100 percent of the participating farms identified and shared one or more of the top three priority areas that involved milker performance, reinforcing the need for milker training and new training resources.

The baseline survey further identified the need to encourage farms to make time for evaluating milking equipment and ensuring that it is maintained in proper working order.

“Four farms had a major equipment issue to correct prior to our evaluation of milker performance. In one instance, the lack of a functional unit alignment device was limiting the milkers’ ability to perform their job well,” Virkler said.

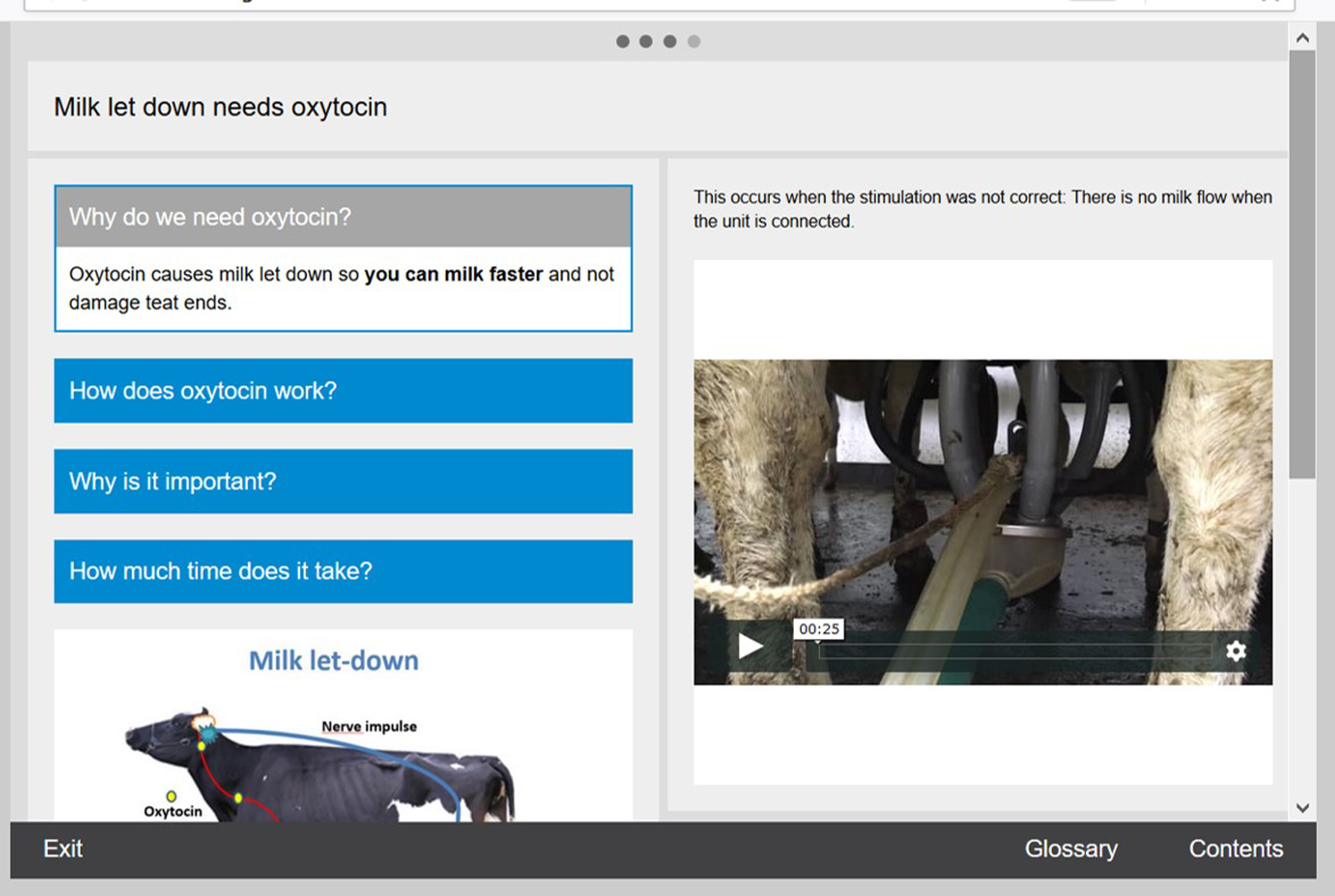

E-learning modules with videos, photos, and text in English and Spanish were developed to demonstrate the seven stages of a proper milking routine.

“We used a story line of a milker needing help so users could relate through their own parlor experience,” Ospina said.

On-farm training sessions introduced employees to the training software format and each individual milker was asked three random questions about the milking procedure to assess pre-training knowledge level. Post-training evaluation showed a positive impact compared to the baseline assessment of teat and cleanliness after milking prep across the 10 farms.

“Post-training we saw a 20 percent improvement in the average cleanliness when milkers better understood why they need to wipe the teat ends. To continue this work regarding optimal cleanliness levels, we are evaluating how to enhance video or graphics in the next edition of the e-learning module and whether in-person training on the specific technique is required,” Virkler explained.

“For the next phase, we will be addressing literacy challenges, the lack of internet familiarity by employees, limited or farm-related internet and wireless access in rural communities, and how to encourage farm scheduling for employee training,” said Ospina.

As part of phase 2 of the NNYADP E-Learning Training Systems for Milk Quality and Parlor Performance project in 2020, Virkler and Ospina are developing an e-learning module focused the basic functions of milking equipment and how that relates to teat end health, flow rates and mastitis prevention.

Funding for the Northern New York Agricultural Development Program is supported by the New York State Legislature and administered by the New York State Department of Agriculture and Markets. NNYADP research reports, fact sheets, and resources are available online at www.nnyagdev.org.

A screen shot of an English version page of the milking procedures module developed as part of the NNYADP-funded E-Learning Training Systems for Milk Quality and Parlor Performance project.